Project Description

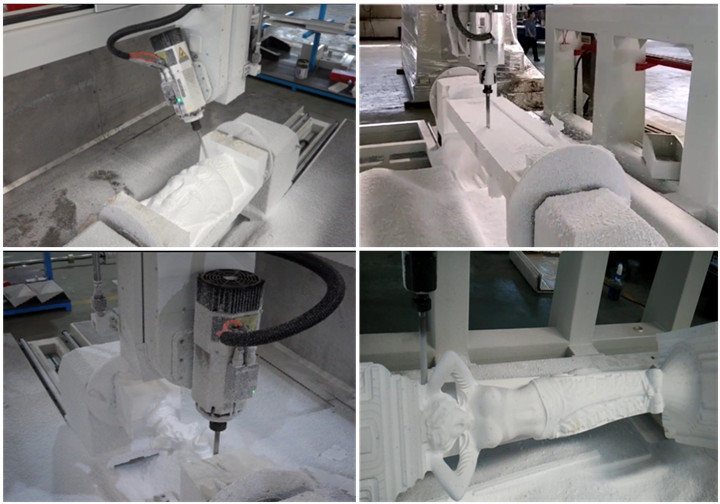

Machine Photos

Machine Features

1. Use the world best Famous brand for the machine’s main parts , to make sure the machine’s working perfectly, High speed and efficiency .

2. Heavy Hard Steel Lath Body, keep the machine’s working High stability.Whole machine is welded with seamless steel structure, dealing with Time-treatment, the stability is excellent, never to be deformed.Full table is with thick Stable plate.

3. Four-row imported ball bearing, widening linear guide rail, self-lubricating sliding block. When engraving, equal force in all directions, to ensure the accuracy and strength.

4. Use the world best brand for the machine’s main parts , such as Taiwan HIWIN Big Size Straight Guide Rail, Japan Yaskawa Servo Motor and Driver system,Taiwan SYNTEC Control System,Germany Ball Screw , France Electronic parts, Taiwan DELTA Inverter, Taiwan Planetary Gearbox,etc.. All of these can make sure the machine’s working perfectly, High speed and efficiency .

5. Automatic self-lubrication system for full machine guide rail. Equipped with high-level precision, High speed and high rigidity linear guide rails,Excellent carry capacity under high load,good anti-wear properties

Technical Parameters

| Model | KB-2030 | Note |

| Lathe body | Thick and Hard Steel structure | sand blast & seasoning |

| X Y Z Effective Working Area | 2000*3000*1000 mm | Can be optional |

| 4th Axis Effective Working Size | 600mm | Can be optional |

| Precision Machining | 0.01mm / 1000mm | |

| Max Traverse Speed | 50000 mm/min | |

| Max Processing Speed | 30000 mm/min | |

| Table Size | 2300*3200 mm | |

| Resolution | 0.001—0.003 mm | |

| Spindle power rate | 7.5KW Air Cooling Spindle | Can be optional |

| Inverter | DELTA | Taiwan |

| X,Y structure | Rack and pinion transmission, Taiwan-made Linear Bigger guide 30mm | Taiwan |

| Z structure | TBI Ballscrew 3210 | Germany |

| Motor of X , Y axis | Yaskawa Servo Motor 1300W | Japan |

| Motor of Z axis and 4th axis | Yaskawa Servo 1300W | Japan |

| Driver | Yaskawa Servo | Japan |

| Standard Power | AC380V - Three Phase (Optional) | |

| Max. idling Speed | 40000 mm/min | |

| Command | G code, HPGL, U00, mmg, plt | |

| Operating System | Syntec system | Taiwan |

| Diameter of Cutter | φ3.175-φ20 | |

| Working Mode | Servo | Japan Yaskawa |

Machine Application

♦ Wood, EPS and non-metallic carbon hybrid materials.

♦ Die and mold industries:

Non-metallic mold: the machine is particularly suitable for automotive foam mold, wooden ship model, wooden model aviation, trains and other wooden mold.

♦ Musical instrument industry:

Can carve three dimension musical instrument, contour cutting.

Working Samples