CO2 laser engraving and cutting machine generates laser beam by laser tube that drived by laser power source, through the refraction of three mirrors, the light is transmitted to the laser head, and then the focus lens installed on the laser head converges the light into a point, which can reach a very high temperature and sublimate the material into gas instantly, which is sucked away by the suction fan, so as to achieve the purpose of engraving and cutting.

1) The main parts of CO2 laser engraving and cutting machine

♥ CO2 laser tube (40w 60w 80w 100w 130w and 150w is optional)

♥ Focus Lens 1 Piece

♥ Red-light Pointer

♥ Motors and drivers (Stepper motor and drivers or AC servo motors and drivers optional)

♥ Control System ( Ruida RD6442S control system2. Support CorelDraw, Photoshop, AutoCAD, Illustrator, InkScape, etc)

♥ Cooling System ( Water Chiller)

♥ Working Table

♦ Up-down table: Mainly used for cutting and engraving thick materials

♦ Knife table: It can be used for engraving and cutting hard materials

♦ Honeycomb table: Mainly used for relatively soft materials, such as leather, fabrics, etc

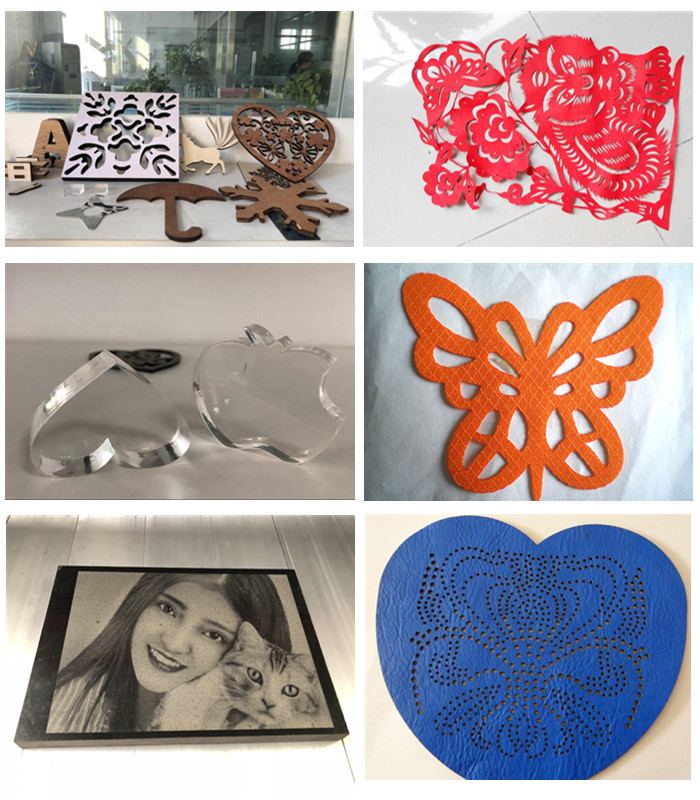

2) What material can be processed by CO2 laser engraving and cutting machine?

Acrylic MDF Wood PVC Color-board Rubber Leather Fabric Paper Plastic ABS bord Paper board.

3) Before you purchase, there are several items you have to confirm

♦ Confirmwhat material you will process by the CO2 laser engraving and cutting Non-metalic material normally need CO2 laser cutting machine, but metal sheet cutting work need fiber laser cutting machine.

♦ Choosesuitable machine working size according to your request. We should note that the larger working size of the machine is not necessarily better.Because machine with larger working size are more expensive, and some machines with poor quality have unstable laser output at various points on large-format surfaces, resulting in different shades of engraving products on the same table, so choosing the right working size is very important.

♦ Check the workpiece type you will process. If you process cylindermaterial, such as glass cup, bottles, bamboo, egg, you have to choose rotary device( rotary attachment) and moving table. The rotary devices are different for holding bottles and egg, so do remember list what type of work you do.

♦ Check laser tube power you need. Wood cutting and paper cutting requires different laser tube power, different cutting thickness requires different power, so this is the important element you should consider too. If your work is mainly engraving, then40w 60w or 80w laser power is a good .If your work is engraving and cutting, just tell us your processing requirement, and then we will offer you the most suitable machine specs.