At present, in the metal processing market, fiber laser cutting machine has gradually replaced CO2 laser cutting machine and traditional processing methods and become the mainstream equipment in sheet metal processing. What are the differences between fiber laser cutting machine and CO2 laser cutting machine, and what are the advantages?

1. Different luminous medium

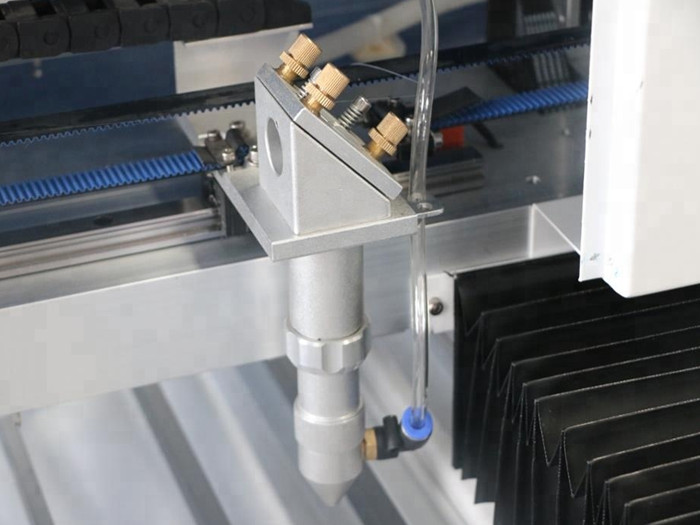

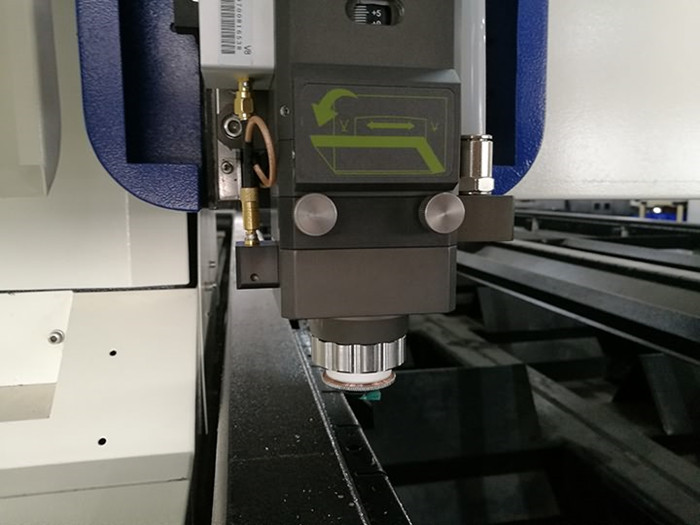

CO2 laser cutting machine, gas is the medium of a laser beam, beam transmission via mirror. Fiber laser is working through the diode and the fiber optic cable transmission, multiple diode pumped laser beam, and then, through the flexible fiber optic cable transmission to laser cutting head, rather than through mirror transmission beam.

2. Fiber laser cutting machine is more compact appearance

Due to the laser transmission structure is different, the same power of fiber in appearance size more compact than CO2 laser cutting machine, so it can save room space.

3. Electro-optic conversion efficiencyof fiber laser cutting machine is higher

With the fiber laser full solid state digital module, a single design, fiber laser cutting machine has higher electro-optic conversion efficiency than co2 laser cutting .Each power supply unit of CO2 laser cutting machine, the actual general utilization is about 8% to 10%, and the fiber laser cutting machine, that figure is around 25% to 30%, between fiber laser cutting system consumes less energy than carbon dioxide cutting system about 3 to 5 times, up to more than 86% of energy efficiency.

4. Fiber laser cutting machine processing effect is better

Fiber laser with short wavelengths, so as to improve the absorptivity of cutting material on the beam, and enable to cut brass, copper, and of non-conductive material. When cutting thickness is 6 mm, 1.5 kW fiber laser cutting machine cutting speed is equivalent to 3 KW CO2 laser cutting machine cutting speed.

5. Fiber laser cutting machine maintenance cost is lower

CO2 laser cutting machine as luminous as a gas medium, because of the CO2 gas purity, inside the cavity will be pollution, need regular cleaning, mirror need to maintenance and calibration, and daily maintenance workload is bigger. For a number kilowatt CO2 laser cutting machine, it needs at least 20000 dollars a year.On average, the device on the daily maintenance of fiber laser cutting is more environmental protection and convenience.